Juppenwerkstatt Riefensberg: Exploring the Textile Manufactory

A stiff and shiny fabric is created in the Juppenwerkstatt Riefensberg in Vorarlberg in a lengthy process; it is folded into hundreds of pleats, from which one of the oldest traditional costumes in Europe, the Juppe, is made.

We congratulate the workshop on this award and visited the site to see the elaborate process of Juppen fabric production in the Juppenwerkstatt Riefensberg. The deep black, shiny and pleated fabric is only produced in the Juppenwerkstatt Riefensberg according to the age-old art of finishing. The machines used are over 100 years old.

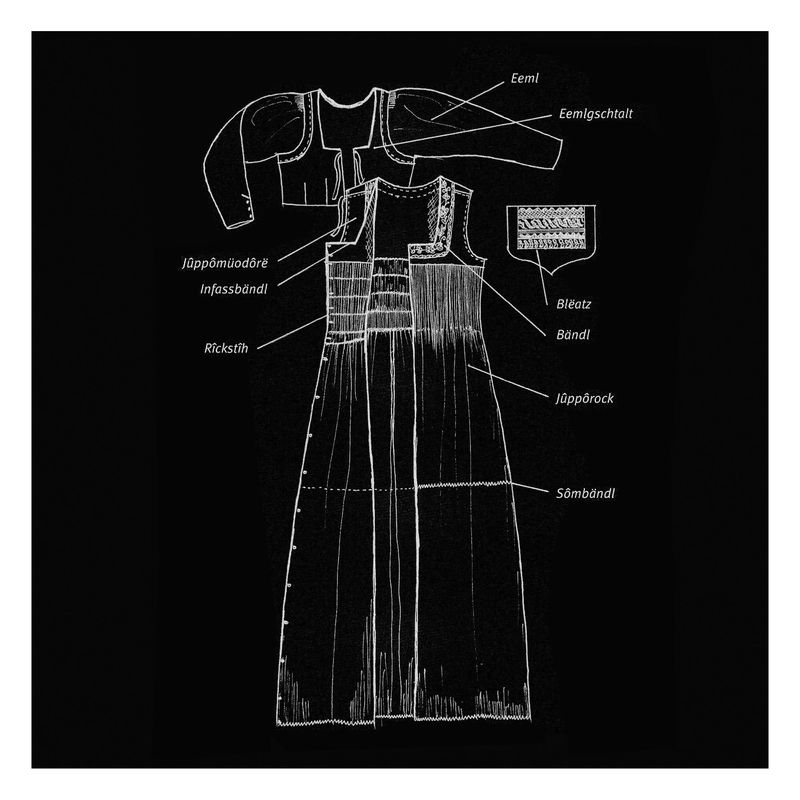

The Bregenzer Forest Juppe is one of the oldest traditional costumes in Europe. Its core piece is a pleated, instep-length, short-bodice dress, the skirt of which has a rectangular basic cut and is sometimes made of regionally produced shiny linen. In addition, the costume is characterized by its valuable decorations.

©Adolf Bereuter

It was with great pleasure that Martina Mätzler and Doris Kranzelbinder gave us a guided tour of their workshop!

The finest black dyed linen is used for fabric finishing. Gluing gives the fabric its stiffness and elasticity. For this purpose, a leather/bone glue is created in an elaborate process.

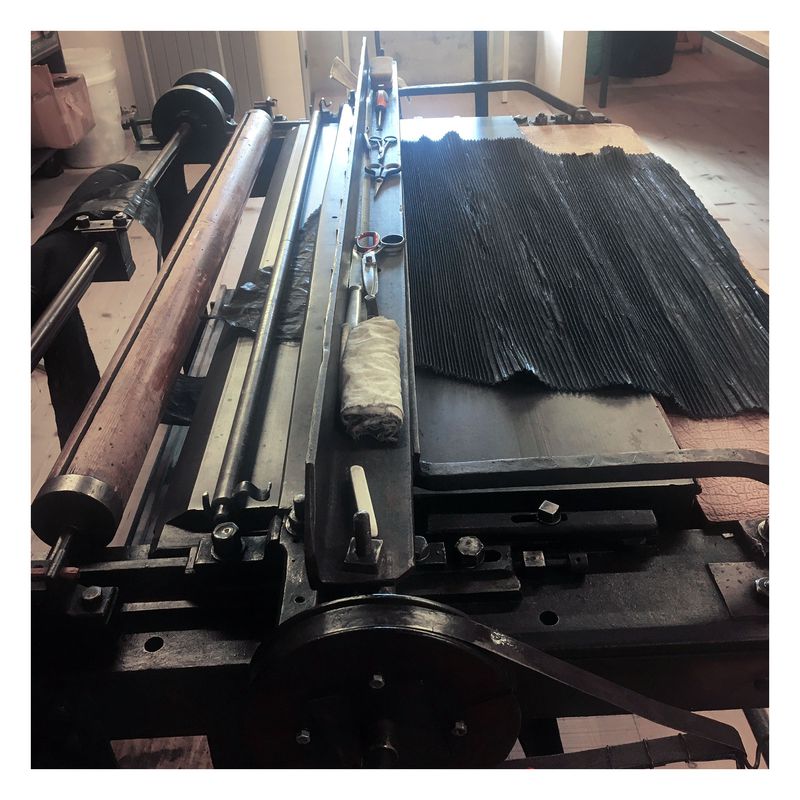

On the glazing machine, which dates back to 1909, the Juppen fabric acquires its characteristic lustre through pressure, friction and heat. With each round, the blackness increases in luminosity. This finishing process takes approx. 90 minutes.

The knowledge of the craft comes from the family of the last Bregenz Forest master dyer, Manfred Fitz from Egg. He and his wife Luise introduced Martina Mätzler to the secret of fabric finishing, which has been closely guarded for generations. Since the opening of the Juppenwerkstatt Riefensberg in 2003, Martina and her team have ensured the continued existence of the traditional Bregenz Forest shiny linen Juppe.

On the pleating machine, a fabric web of 480 cm in length is laid in about 500, 7-mm-deep horizontal pleats. For this purpose, the fabric requires suitable moisture and is therefore placed in an open earth pit for a few minutes beforehand. Two people work on the pleating machine; while one person pleats, the other rolls up the finished fabric and binds it seven times.

Drawing: Martina Mätzler, 2013

The black-bodice traditional costume from Bregenz developed from an early medieval working garment. Its silhouette and black colouring are reminiscent of the influence of Spanish fashion. Annemarie Bönsch, one of the best-known costume historians in the German-speaking world, describes the Bregenz Forest Juppe as one of the oldest and most valuable traditional costumes in Europe.

About 2,500 slip stitches, so-called ‘Ricken’, are required on the upper part of the dress to create the desired silhouette and stretch. This sewing technique allows the wearer to breathe freely.

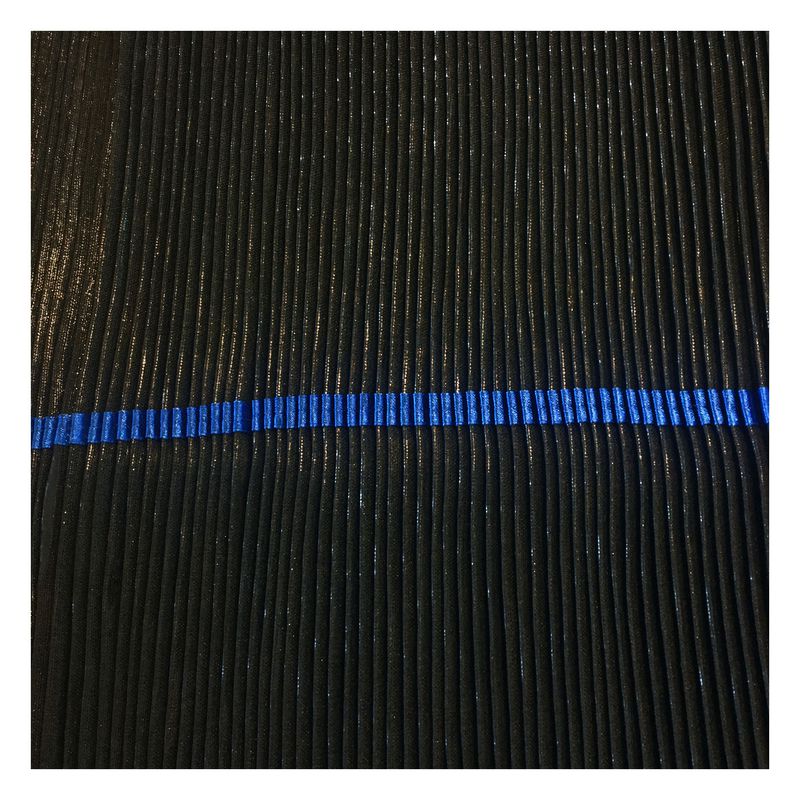

Since the linen could originally only be woven in narrow panels, it had to be pieced together. An indigo hem tape was added to the hem seam and this feature has remained to this day. To increase the dimensional stability of the folds, Juppen fabrics are kept hanging and rolled for six months before they can be further processed.

Juppen fabrics are not washable. Careful handling of the costume is also required. Storage of a Juppe is rolled, placed in a stocking and hung up.

Used Juppen fabrics are collected and reprocessed in the workshop. They then go through the entire process again.

The Juppenwerkstatt is located in the former Krone Inn. The building was completely gutted and converted into an exhibition space with a workshop by Bregenz architect Gerhard Gruber.

Learn more about the Bregenzer Forest Juppe in this documentary film:

Beispiele zur Kostümkunde: Die Juppe – Das Oberkleid der Bregenzerwälder Frauentracht

For more information, exhibitions and images, visit

Juppenwerkstatt Riefensberg

Dorf 52

A-6943 Riefensberg Opening Hours

1 May - 31 October 2023

We visited the Juppenwerkstatt Riefensberg in May 2022, as part of our ongoing

project Friendly New Products – Rethinking Design Processes.